Beyond Powder Coating: Our Light Mechanical Assembly Services

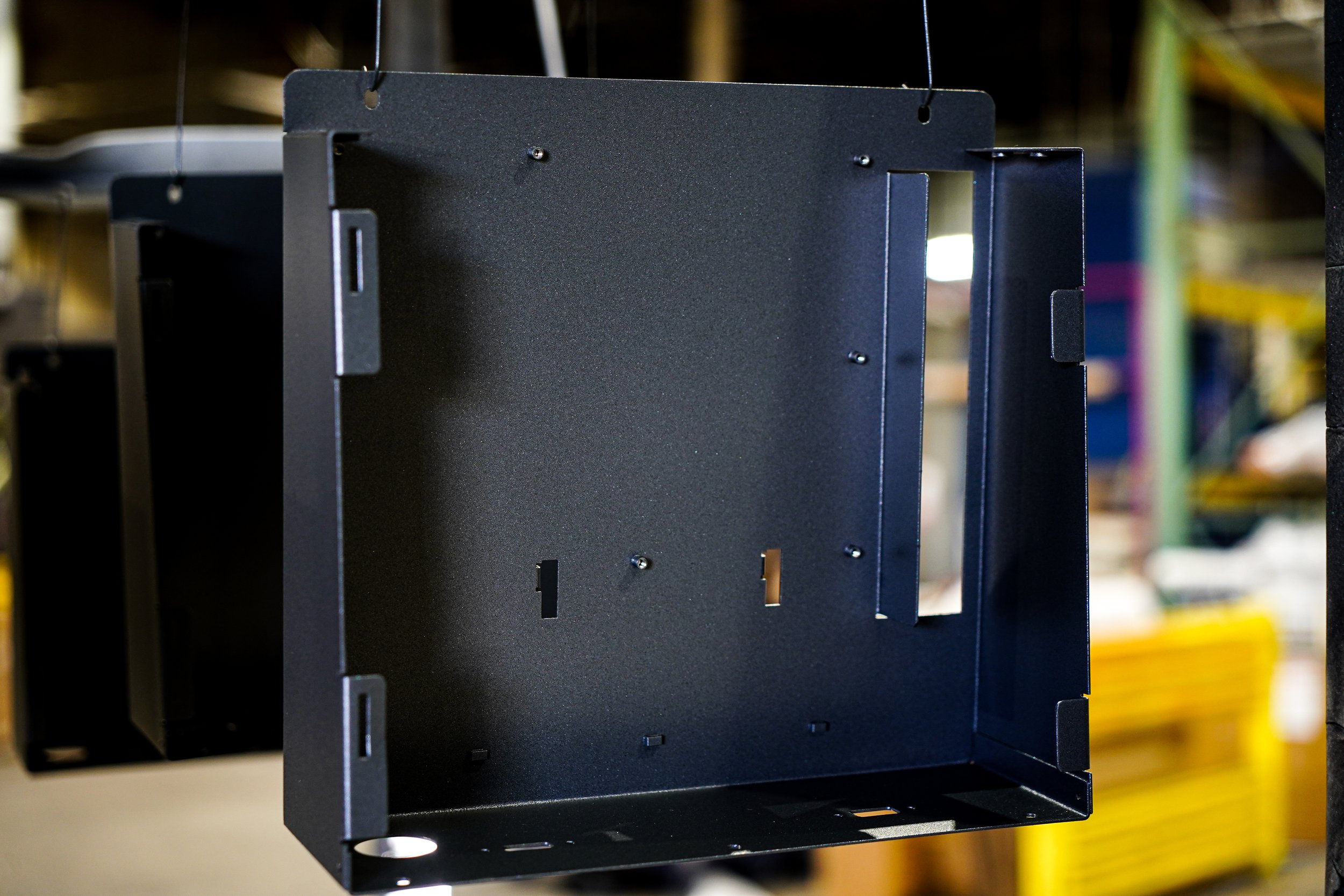

At Applied Powdercoat, we understand that sometimes customers need a little help getting their parts over the finish line. That’s why we’re happy to provide light mechanical assembly services in addition to our high-quality powder coat services.

Proper assembly techniques and tools are essential to maintain the integrity of powder coating and the overall quality of the finished product. With this service, Applied Powdercoat can be the one-stop solution for all your powder coating and assembly needs.

Types of Light Mechanical Assembly Services We Offer

After your parts are powder coated, our team can help finish the job with gasket installation and nuts and bolts assemblies.

Applied Powdercoat often uses external gaskets for shipping brackets to prevent the machines they're fastened to from becoming scratched. Gaskets also help mitigate the impact of transportation-related challenges—including vibration, shock, friction, and environmental factors—to ensure parts arrive at their destination in excellent condition.

We apply other gaskets inside parts near motors to suppress sound and dissipate heat. These gaskets also assist with maintaining proper sealing, preventing contamination, isolating vibrations, and contributing to the overall safety and efficiency of motor-driven systems. Such functions are crucial for the performance, longevity, and compliance of various industrial and automotive applications.

Our shop also provides nuts and bolts assemblies when your parts need to be fastened together after powder coating.

When it comes to the part size for assemblies, our team is pretty flexible! As long as the parts are bigger than a bread box and smaller than a room, we have the capabilities and experience to build assemblies to your exact specifications.

Applied Powdercoat’s Light Mechanical Assembly Process

In our shop, we perform powder coat services before moving on to assembly services. For example, after powder coating several parts, you may need us to fasten parts one, two, three, and four together. In another instance, some parts may require gasket installation before completion.

Applied Powdercoat can source gaskets and hardware if necessary. With gaskets, we can hand-cut the seal or buy a premade component. We’ll determine all these details in the quote phase. The drawing usually tells us whether gaskets or other assembly is required.

How Customers Benefit From Our Light Mechanical Assembly Services

After we powder coat and assemble your parts, they’re ready to go. You don’t have to buy and install gaskets or spend time on nuts and bolts assembly, which saves you time and labor.

Applied Powdercoat offers light mechanical assembly to simplify the order process and provide our customers with the highest level of service in our industry. When our shop handles powder coating and assembly, we retain better control over the quality of the final product. We can ensure your powder-coated parts are properly protected and that the assembly is done correctly.

Our shop serves a variety of industries—including aerospace and defense—and offers a wide range of metal finishing services to meet your requirements. With more than 30 years of experience, we’ve firmly established ourselves in the powder coating industry. Our professionalism is based on quality, responsiveness, and customer service.

If you’re looking for a full-service facility that offers powder coat services for high-volume production, mid to low-volume orders, and custom projects—request a quote from Applied Powdercoat today.